A Power Factor Correction Unit improves energy efficiency by reducing reactive power in electrical systems. It optimizes the power factor, lowering electricity costs.

Power Factor Correction Units (PFCUs) are crucial for enhancing the efficiency of electrical systems. They work by minimizing the reactive power, which doesn't perform any useful work but contributes to the total power consumption. Businesses and industries benefit from installing PFCUs because they help in reducing electricity bills and improving the lifespan of electrical equipment.

Poor power factor can lead to increased demand charges from utilities. By correcting this, PFCUs ensure that systems operate more efficiently and economically. They are essential in environments where large inductive loads, such as motors and transformers, are prevalent.

Introduction To Power Factor Correction

Power Factor Correction (PFC) is vital in electrical systems. It helps improve energy efficiency. PFC ensures optimal use of electrical power.

Basics Of Power Factor

The power factor measures how effectively electrical power is used. It is the ratio of real power to apparent power. Real power performs useful work. Apparent power is the total power in the system.

A higher power factor indicates efficient power usage. A lower power factor means wastage of electrical power. This results in higher energy bills.

| Power Type | Description |

|---|---|

| Real Power | Performs actual work |

| Apparent Power | Total power in the system |

Importance Of Power Factor Correction

Correcting the power factor has many benefits. It reduces energy costs. It improves the lifespan of electrical equipment. It also increases the capacity of the power system.

- Lower energy bills

- Extended equipment life

- Increased system capacity

PFC units help achieve these benefits. They adjust the power factor to near unity. This ensures efficient power usage.

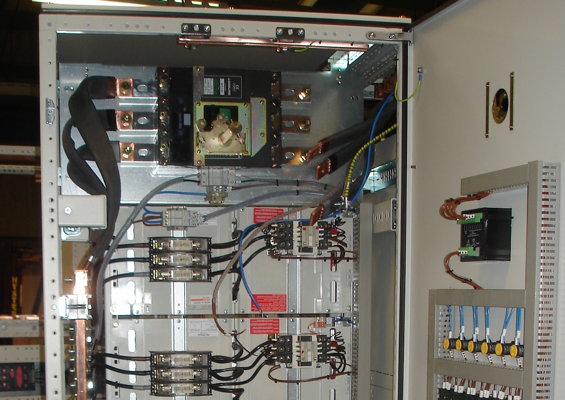

Credit: www.kane-engineering.co.uk

Types Of Power Factor Correction Units

Power Factor Correction Units (PFCUs) are essential for improving energy efficiency. They help reduce power losses and lower electricity bills. There are mainly two types of PFCUs: Static Correction Units and Automatic Correction Units. Each type has its unique features and benefits.

Static Correction Units

Static Correction Units are simple and cost-effective. They are ideal for small and medium-sized loads. These units use capacitors to correct the power factor. Installation is straightforward, making them user-friendly.

- Suitable for fixed loads

- Low initial cost

- Easy installation

Static units are best for applications where the load does not change much. They are reliable and have low maintenance needs. But they may not be efficient for variable loads.

Automatic Correction Units

Automatic Correction Units are advanced and versatile. They are perfect for varying loads. These units use a combination of capacitors and controllers. The controllers adjust the power factor in real-time.

- Ideal for dynamic loads

- Real-time adjustment

- Higher efficiency

Automatic units are more expensive than static ones. But their efficiency and adaptability make them a great investment. They ensure optimal power factor correction at all times.

| Feature | Static Correction Units | Automatic Correction Units |

|---|---|---|

| Load Type | Fixed | Variable |

| Cost | Low | High |

| Efficiency | Moderate | High |

| Maintenance | Low | Moderate |

How Power Factor Correction Works

Power Factor Correction (PFC) improves the efficiency of electrical systems. It reduces power losses and helps save energy costs. Understanding how PFC works is essential for maximizing its benefits.

The Role Of Capacitors

Capacitors play a crucial role in power factor correction. They store and release electrical energy. This helps balance the reactive power in the system.

Reactive power is the unused power in electrical systems. It creates extra load and reduces efficiency. Capacitors supply this reactive power, freeing up more usable power.

Capacitors are often installed in parallel with the load. This placement allows them to counteract the inductive effects of motors and transformers.

Calculating The Correct Level Of Correction

Properly sizing the power factor correction unit is key. Use the following steps to calculate the correct level of correction:

- Measure the current power factor of the system.

- Determine the desired power factor.

- Calculate the required reactive power (kVAR) using the formula:

kVAR = kW (tan(acos(current PF)) - tan(acos(desired PF)))

Here, kW represents the system's active power. PF stands for power factor.

| Current Power Factor | Desired Power Factor | Required kVAR |

|---|---|---|

| 0.75 | 0.95 | 20 kVAR |

| 0.80 | 0.95 | 15 kVAR |

Use these calculations to select the appropriate PFC unit. This ensures optimal efficiency and cost savings.

Benefits Of Power Factor Correction

Power Factor Correction Units (PFCUs) offer significant benefits for both residential and commercial settings. By improving the power factor, these units enhance the efficiency and performance of electrical systems. Below, we delve into the key benefits of using a Power Factor Correction Unit.

Reduced Energy Bills

One of the primary benefits of a PFCU is reduced energy bills. By optimizing the power factor, the unit decreases energy waste. This leads to lower electricity costs. Businesses and households can see substantial savings on their energy bills. Improved efficiency means that less energy is required to perform the same tasks. This cost-saving aspect is especially critical for large-scale operations.

Enhanced Equipment Performance

Power Factor Correction Units also enhance equipment performance. When the power factor is optimized, electrical devices operate more efficiently. This results in less wear and tear on machinery. Equipment lasts longer and requires less maintenance. In industrial settings, this can mean significant savings on repair and replacement costs.

Enhanced performance also means that equipment runs cooler. This reduces the risk of overheating and extends the lifespan of electrical devices. Improved performance translates to better productivity and reliability.

Selecting The Right Power Factor Correction Unit

Choosing the right Power Factor Correction Unit (PFCU) is crucial. It helps in managing energy efficiently. Below are key factors to consider.

Assessing Your Needs

First, you need to assess your needs. Determine your current power factor. Identify the load types you are using. This data helps in selecting an appropriate unit.

- Measure your power factor: Use a power meter to get accurate readings.

- Identify load types: Are you using inductive or resistive loads?

- Calculate required correction: Find out how much correction is needed.

A clear understanding of your needs helps in making an informed choice.

Comparing Unit Specifications

Next, compare the specifications of different units. Make sure the unit matches your requirements.

| Specification | Unit A | Unit B |

|---|---|---|

| Correction Capacity | 50 kVAR | 100 kVAR |

| Voltage Rating | 400V | 415V |

| Efficiency | 95% | 98% |

| Size | Compact | Medium |

Look for units that offer high efficiency. Efficiency saves energy and reduces costs.

Consider the voltage rating and correction capacity. Make sure they match your system requirements.

Check the size of the unit. A compact unit might be easier to install.

Installation And Maintenance

Proper installation and maintenance of your Power Factor Correction Unit (PFCU) are essential. They ensure the unit's efficiency and longevity. Below, we'll discuss key aspects of professional installation and routine maintenance tips to keep your PFCU in top condition.

Professional Installation

Hiring a professional for PFCU installation is crucial. It ensures the unit is set up correctly and safely. Professionals have the expertise to handle electrical systems. They ensure all components are properly connected. This reduces the risk of faults or failures.

A professional installer will:

- Assess the electrical system's current state.

- Identify the best location for the PFCU.

- Install the unit according to manufacturer guidelines.

- Test the system to confirm proper operation.

Routine Maintenance Tips

Routine maintenance helps keep your PFCU running smoothly. Follow these simple tips to ensure optimal performance:

- Regular Inspections: Check the unit every six months.

- Clean Components: Remove dust and debris from the unit.

- Tighten Connections: Ensure all electrical connections are tight.

- Monitor Performance: Track the unit's efficiency regularly.

- Replace Worn Parts: Change capacitors or fuses as needed.

Use a table to keep track of maintenance tasks:

| Task | Frequency |

|---|---|

| Inspect the unit | Every 6 months |

| Clean components | Every 6 months |

| Tighten connections | Every 6 months |

| Monitor performance | Monthly |

| Replace worn parts | As needed |

By following these tips, you ensure your PFCU operates efficiently. Regular maintenance extends the unit's lifespan and reduces downtime.

Case Studies: Success Stories

Discover how Power Factor Correction Units (PFCUs) have transformed various sectors. These success stories highlight the benefits of implementing PFCUs across different applications. Learn from these real-world examples to understand the impact of PFCUs.

Industrial Applications

Many industries have experienced significant benefits from using Power Factor Correction Units. Here are some notable examples:

| Industry | Outcome |

|---|---|

| Manufacturing Plant | Reduced energy bills by 20% |

| Textile Industry | Improved equipment lifespan by 15% |

| Steel Production | Enhanced operational efficiency |

- Manufacturing Plant: A large factory installed PFCUs. They saw a 20% reduction in energy bills. This led to significant savings on operational costs.

- Textile Industry: A textile company reported a 15% increase in equipment lifespan. They credited the improvement to the installation of PFCUs.

- Steel Production: A steel manufacturer noted enhanced operational efficiency. This was achieved after integrating PFCUs into their system.

Commercial Successes

Commercial establishments have also reaped the benefits of Power Factor Correction Units. These examples showcase the positive impacts:

- Shopping Malls: A large mall reduced its energy consumption by 25%. The installation of PFCUs made a significant difference.

- Office Buildings: An office complex reported a 30% decrease in energy wastage. This was a direct result of using PFCUs.

- Hotels: A major hotel chain saw a 20% reduction in electricity costs. They attributed this to their new PFCU system.

| Commercial Establishment | Outcome |

|---|---|

| Shopping Mall | Reduced energy consumption by 25% |

| Office Building | Decreased energy wastage by 30% |

| Hotel Chain | Reduced electricity costs by 20% |

These case studies demonstrate the tangible benefits of Power Factor Correction Units. Both industrial and commercial sectors have seen improvements in energy efficiency and cost savings. This proves the value of investing in PFCUs.

Navigating Challenges In Power Factor Correction

Power factor correction units (PFCUs) are essential for efficient energy use. However, various challenges arise during their implementation. Addressing these challenges is crucial for optimal performance.

Common Pitfalls

Many issues can occur during power factor correction. Understanding these pitfalls helps in avoiding them.

- Incorrect Sizing: Choosing the wrong size can lead to inefficiency.

- Poor Installation: Improper installation affects performance and safety.

- Overcompensation: Overcorrecting the power factor can cause voltage instability.

- Undercompensation: Failing to correct the power factor results in energy loss.

- Harmonic Distortion: Harmonics can interfere with PFCU operation.

Advanced Troubleshooting Techniques

Advanced techniques can solve complex PFCU issues. These techniques ensure reliable and efficient operation.

- Thermal Imaging: Use thermal cameras to detect overheating components.

- Electrical Testing: Conduct regular tests to check circuit integrity.

- Software Analysis: Employ software tools for detailed system analysis.

- Harmonic Filters: Install filters to reduce harmonic interference.

- Regular Maintenance: Schedule maintenance to prevent unexpected failures.

Combining these techniques improves the reliability of PFCUs. Ensuring proper operation reduces energy costs and enhances system efficiency.

Frequently Asked Questions

What Is A Power Factor Correction Unit?

A power factor correction unit improves energy efficiency by optimizing the power factor of electrical systems. It reduces energy losses and lowers electricity costs.

How To Calculate Power Factor Correction?

To calculate power factor correction, first measure the current power factor. Determine the desired power factor. Use the formula: kVAR = kW × (tan θ1 - tan θ2) where θ1 is the angle for current power factor and θ2 is for desired power factor.

Install capacitors based on kVAR value.

What Is The Unit Of Power Factor?

The unit of power factor is dimensionless. It is expressed as a number between 0 and 1.

What Is The Power Factor Correction Method?

Power factor correction improves energy efficiency by adjusting the power factor of electrical systems. It reduces energy waste and lowers electricity bills. Methods include using capacitors or synchronous condensers to counteract inductive loads. This optimization leads to better performance and cost savings.

Conclusion

Enhancing your electrical system's efficiency with a Power Factor Correction Unit is crucial. It reduces energy waste and costs. Businesses benefit from improved performance and lower electricity bills. Implementing this unit leads to long-term savings and sustainability. Invest in a Power Factor Correction Unit to optimize your energy usage and enhance overall productivity.