Power factor correction improves energy efficiency by reducing reactive power in electrical systems. It lowers energy costs and enhances equipment performance.

Power factor correction is crucial for optimizing electrical systems. It involves adjusting the power factor to be as close to unity as possible. This process minimizes wasted energy, reduces electricity bills, and extends the lifespan of electrical equipment. Businesses benefit from lower energy costs and improved system reliability.

Implementing power factor correction can also help meet regulatory requirements and avoid penalties. Various methods, such as capacitor banks and synchronous condensers, can be used for this purpose. Understanding and applying power factor correction ensures efficient, cost-effective, and sustainable energy use.

Get Free Quote?

For Power Factor Correction.

Introduction To Power Factor

Power Factor is a critical concept in electrical systems. It impacts the efficiency of power usage. Understanding Power Factor can help you save energy and reduce costs. In this section, we will explore what Power Factor is and why it matters.

What Is Power Factor?

Power Factor measures how effectively electrical power is used. It is the ratio of real power (used to do work) to apparent power (total power supplied). The formula for Power Factor is:

Power Factor = Real Power (kW) / Apparent Power (kVA)

Power Factor values range from 0 to 1. A Power Factor of 1 means all the power is effectively used. A lower Power Factor indicates inefficiency.

Why Is Power Factor Important?

A high Power Factor is crucial for several reasons:

- Energy Efficiency: A high Power Factor means less energy is wasted.

- Cost Savings: Utility companies may charge more for low Power Factor.

- Equipment Longevity: Efficient power use reduces stress on electrical equipment.

Improving Power Factor can lead to significant benefits. It helps in reducing electricity bills and enhancing system performance.

Impact On Electrical Systems

Power factor correction plays a crucial role in electrical systems. It ensures efficient power usage and reduces waste. Understanding its impact can help maintain system stability and performance.

Effects Of Low Power Factor

A low power factor can lead to several issues in electrical systems. It increases the current flow, which can cause overheating. This can damage equipment and reduce its lifespan.

Voltage drops are another consequence of low power factor. This can lead to inefficient power distribution. As a result, devices may not operate correctly.

Here are some common effects of low power factor:

- Overheating of transformers and generators

- Increased losses in electrical components

- Reduced system capacity

Power Factor And Energy Costs

Improving the power factor can significantly reduce energy costs. A high power factor means efficient use of electricity. This reduces the amount of wasted energy.

Businesses can save money by correcting their power factor. This leads to lower electricity bills. Here are some benefits of a high power factor:

- Lower energy consumption

- Reduced demand charges

- Improved voltage regulation

| Power Factor | Energy Consumption | Cost Savings |

|---|---|---|

| Low | High | Low |

| High | Low | High |

By maintaining a high power factor, electrical systems can operate efficiently. This not only saves energy but also reduces costs. It is a win-win situation for both the environment and the economy.

Basics Of Power Factor Correction

Understanding the Basics of Power Factor Correction helps improve energy efficiency. Power Factor Correction (PFC) aims to adjust the power factor of an electrical system. The power factor measures how effectively electrical power is converted into useful work output. A low power factor indicates poor efficiency. This can lead to higher electricity bills and additional strain on the electrical infrastructure.

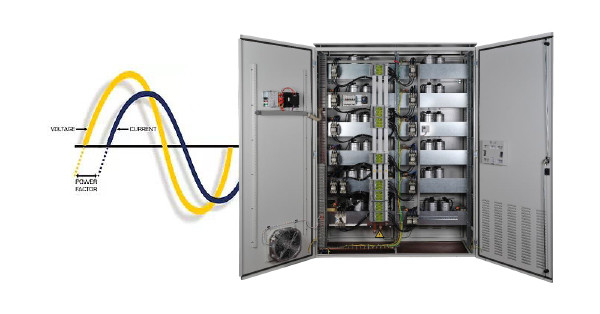

Methods To Improve Power Factor

There are several methods to improve power factor. These methods can be used individually or in combination:

- Capacitor Banks: Adding capacitor banks helps to offset inductive loads.

- Synchronous Condensers: These are synchronous motors that improve power factor.

- Phase Advancers: Used for induction motors to enhance power factor.

Capacitors In Correction

Capacitors play a crucial role in power factor correction. They help to neutralize the lagging current caused by inductive loads. This makes them one of the most common solutions for PFC.

| Type of Load | Typical Correction Method |

|---|---|

| Inductive Loads (Motors) | Capacitor Banks |

| Lighting Systems | Individual Capacitors |

| Mixed Loads | Automatic Capacitor Banks |

Using capacitors helps to reduce energy losses. This leads to improved energy efficiency and reduced electricity costs. In many cases, capacitors are installed directly in the electrical panels. They help to correct the power factor at the source.

Economic Benefits Of Correction

Power Factor Correction (PFC) can provide significant economic benefits. These benefits can help businesses and households save money. Below we explore the main economic advantages of PFC.

Reducing Electricity Bills

Correcting the power factor reduces electricity bills. This is because it decreases the amount of reactive power. Reactive power does not do useful work. Most utility companies charge for both active and reactive power. By reducing reactive power, you lower your total electricity consumption. This leads to lower electricity bills.

| Initial Power Factor | Corrected Power Factor | Percentage Savings |

|---|---|---|

| 0.75 | 0.95 | 20% |

| 0.80 | 0.95 | 15% |

| 0.85 | 0.95 | 10% |

Prolonging Equipment Life

Power Factor Correction also extends the life of electrical equipment. Poor power factor causes equipment to work harder. This leads to overheating and wear and tear. Correcting the power factor reduces the stress on equipment.

- Lower maintenance costs

- Fewer replacements needed

- Reduced downtime

Prolonged equipment life means more savings. Businesses can allocate funds to other important areas. PFC is an investment that pays off over time.

Environmental Considerations

Power factor correction helps the environment. It reduces wasted energy and cuts carbon emissions. Understanding its environmental benefits is crucial for a sustainable future.

Lowering Carbon Footprint

Improving power factor cuts carbon emissions. Less energy waste means fewer fossil fuels burned. This directly reduces greenhouse gases.

Businesses can reduce their carbon footprint. They achieve this by optimizing their electrical systems. This step is beneficial for the planet.

Energy Conservation Incentives

Governments offer energy conservation incentives. These incentives encourage businesses to improve power factor. They can come in the form of tax breaks or rebates.

Energy-efficient systems save money. They also help the environment. Investing in power factor correction is a win-win.

| Incentive Type | Benefit |

|---|---|

| Tax Breaks | Reduce tax liability |

| Rebates | Lower initial investment cost |

Companies should explore these incentives. They not only save money but also support environmental goals.

Credit: www.allaboutcircuits.com

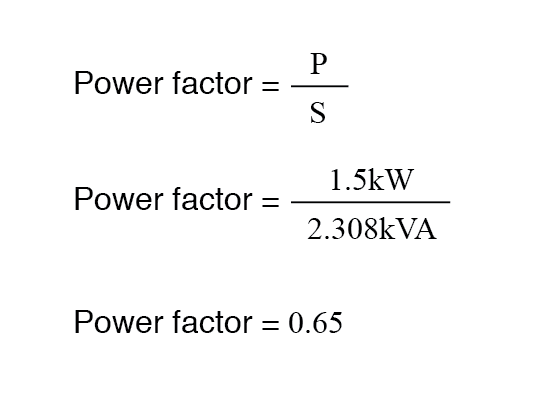

Calculating Power Factor

Understanding how to calculate the power factor is crucial for efficient energy use. A precise calculation can help reduce energy costs and improve system performance. This section will guide you through the necessary tools, techniques, and interpretation of power factor readings.

Tools And Techniques

To calculate power factor, you need specific tools and follow certain techniques:

- Multimeter: Measures voltage and current.

- Power Meter: Directly measures the power factor.

- Oscilloscope: Visualizes waveforms for voltage and current.

Using these tools, follow these steps:

- Measure the voltage (V) and current (I).

- Measure the real power (P) in watts.

- Calculate the apparent power (S) using the formula S = V x I.

- Determine the power factor (PF) using the formula PF = P / S.

Interpreting Power Factor Readings

Interpreting power factor readings helps identify inefficiencies in your system:

| Power Factor Range | Interpretation |

|---|---|

| 0.95 - 1.00 | Excellent: The system is highly efficient. |

| 0.85 - 0.94 | Good: The system operates efficiently but can improve. |

| 0.75 - 0.84 | Fair: The system is moderately efficient. |

| Below 0.75 | Poor: The system has significant inefficiencies. |

A high power factor close to 1.00 indicates efficient energy use. Lower power factors suggest wasted energy and higher costs. Regular monitoring and correction can optimize your system's performance.

Real-world Applications

Power Factor Correction (PFC) has a wide range of practical uses. It improves electrical efficiency and reduces costs. Here, we explore its real-world applications.

Case Studies: Industrial Success

Many industries have benefited from Power Factor Correction. Let's look at some success stories.

| Industry | Problem | Solution | Result |

|---|---|---|---|

| Manufacturing | High energy costs | Installed PFC capacitors | 30% cost reduction |

| Food Processing | Equipment inefficiency | PFC and voltage regulation | Improved productivity |

| Textiles | Frequent power outages | Advanced PFC systems | Reduced downtime |

Adoption In Renewable Energy Systems

Renewable energy systems also use Power Factor Correction. It makes these systems more efficient and reliable.

- Solar Panels: PFC helps manage fluctuating power outputs.

- Wind Turbines: PFC reduces reactive power and enhances stability.

- Hydroelectric Plants: PFC ensures smooth operation and better energy conversion.

Power Factor Correction in renewable systems offers numerous benefits:

- Improves energy efficiency.

- Reduces operational costs.

- Enhances system reliability.

Navigating Regulations And Standards

Understanding regulations and standards for Power Factor Correction is crucial. These guidelines ensure systems are efficient and compliant. Compliance helps in reducing energy waste and cutting costs.

Compliance With Power Quality Standards

Power quality standards ensure systems deliver stable electricity. Compliance prevents equipment damage and improves performance. Adhering to these standards safeguards your electrical infrastructure.

Key standards include:

- IEEE 519

- IEC 61000-3-2

- EN 50160

These standards address harmonic distortion, voltage levels, and power factor. Meeting these standards ensures smooth operations.

International Power Factor Norms

Different countries have unique power factor norms. Understanding these norms is essential for global operations.

Here are some examples:

| Country | Power Factor Requirement |

|---|---|

| United States | 0.95 |

| European Union | 0.90 |

| India | 0.85 |

Adhering to these norms ensures compliance and efficiency. It also helps avoid penalties and improve system performance.

Future Of Power Factor Correction

The future of Power Factor Correction (PFC) is evolving rapidly. Technological advancements are driving significant changes. These changes promise efficiency and sustainability. In this section, we explore the future of PFC under two key subheadings: Technological Advancements and Predictions and Trends.

Technological Advancements

Technology is crucial in the evolution of Power Factor Correction. New innovations are emerging in the field. These innovations aim to optimize energy use.

One of the key advancements is the use of smart meters. Smart meters provide real-time data. This data helps in making informed decisions. They also help in detecting inefficiencies quickly.

Another important advancement is in automation. Automated PFC systems adjust themselves. They adapt to changing loads without manual intervention. This increases efficiency and reduces human error.

Additionally, the integration of IoT is becoming common. IoT devices monitor and control PFC systems remotely. This allows for predictive maintenance and reduces downtime.

| Technology | Impact |

|---|---|

| Smart Meters | Provide real-time data for better decisions |

| Automation | Adjusts PFC systems automatically |

| IoT Integration | Monitors and controls remotely |

Predictions And Trends

Experts predict several trends in Power Factor Correction. One major trend is the rise of renewable energy sources. Solar and wind power are becoming more popular. This shift demands more efficient PFC systems.

Another trend is the focus on sustainability. Companies are adopting eco-friendly practices. Efficient PFC systems reduce energy waste. This aligns with global sustainability goals.

There is also a growing trend towards customized solutions. Businesses need PFC systems tailored to their specific needs. Custom solutions ensure maximum efficiency and cost-effectiveness.

- Rise of renewable energy sources

- Focus on sustainability

- Customized PFC solutions

The future of Power Factor Correction looks promising. With technological advancements and emerging trends, the industry is set for significant growth.

Credit: www.iskra.eu

Credit: www.a-m-c.com

Frequently Asked Questions

How Do You Calculate The Power Correction Factor?

Calculate the power correction factor by dividing the real power (kW) by the apparent power (kVA). The formula is: Power Factor = kW / kVA.

How Do You Choose A Power Factor Correction?

Choose a power factor correction by analyzing your electrical load, measuring power factor, and selecting appropriate capacitors. Consult an expert.

How To Correct Power Factor At Home?

Install a power factor correction device. Use energy-efficient appliances. Avoid overloading circuits. Consult an electrician for advice.

Should The Power Factor Be 0.8 Or 1?

The ideal power factor is 1. A power factor of 0. 8 indicates inefficiency and higher energy costs. Aim for a power factor close to 1 for optimal performance.

Conclusion

Optimizing power factor offers numerous benefits. It reduces energy costs and increases electrical system efficiency. Implementing power factor correction can extend equipment lifespan. Businesses can achieve sustainability goals and improve operational performance. Investing in power factor correction is a smart move for long-term savings and reliability.