Solar Panels Recycling

About This Article:

We are publishing this article to keep the readers informed that, the study shows solar panels can recycled and worn out panels will not create any environmental threat to us in future. The content of this article is being copied from various resources available over internet and the credit goes to every individuals who did take the effort to publish.

The Lifetime of Solar Panels

How long do solar panels last? A question that most people have in mind when considering solar panels. According to studies, the life expectancy of solar panels is about 30 years before decommissioning.

Disposal of Solar Panels

Solar Panel Waste

Solar Panel Recycling Processes

Silicon Based Solar Panel Recycling

Thin-Film Based Solar Panel Recycling

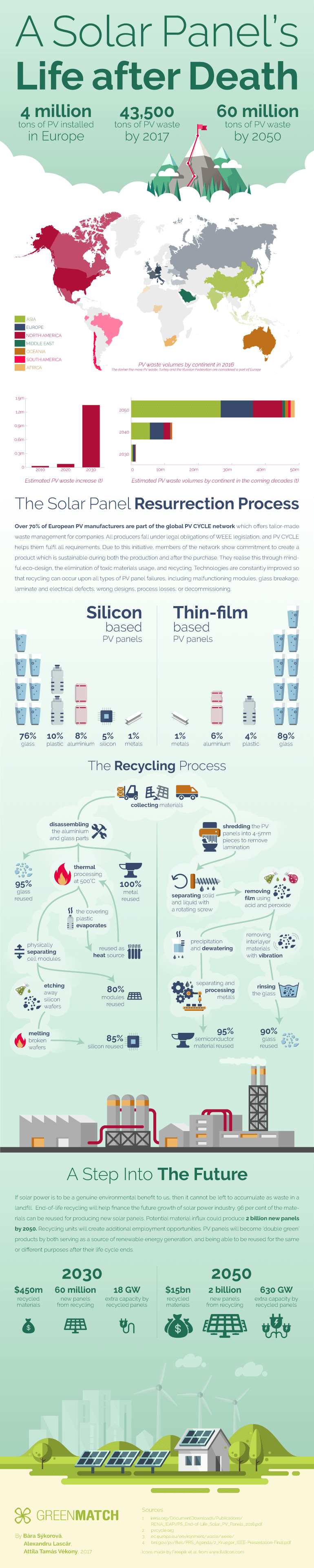

Here is one info graphic on this article published on internet,